How Commercial Recycling Systems Work: A Complete Guide to Understanding Business Recycling

Commercial recycling has become more than just an environmental responsibility. It's a smart business practice that saves money, reduces waste, and helps companies meet sustainability goals. But how does the entire system work, from the moment you toss a bottle into a bin until it becomes a new product?

Let's break it down.

What Are Commercial Recycling Systems?

Commercial recycling involves collecting, sorting, and processing recyclable materials generated by businesses, like packaging, paper, electronics, food waste, and textiles, to divert them from landfills. Unlike residential programs, commercial systems handle larger volumes and more diverse materials.

The process includes everything from the bins employees use daily to the sophisticated machinery that separates materials at processing facilities. When designed correctly, these systems reduce disposal costs, cut down landfill waste, and turn discarded items into valuable resources.

The Three Main Stages of Commercial Recycling

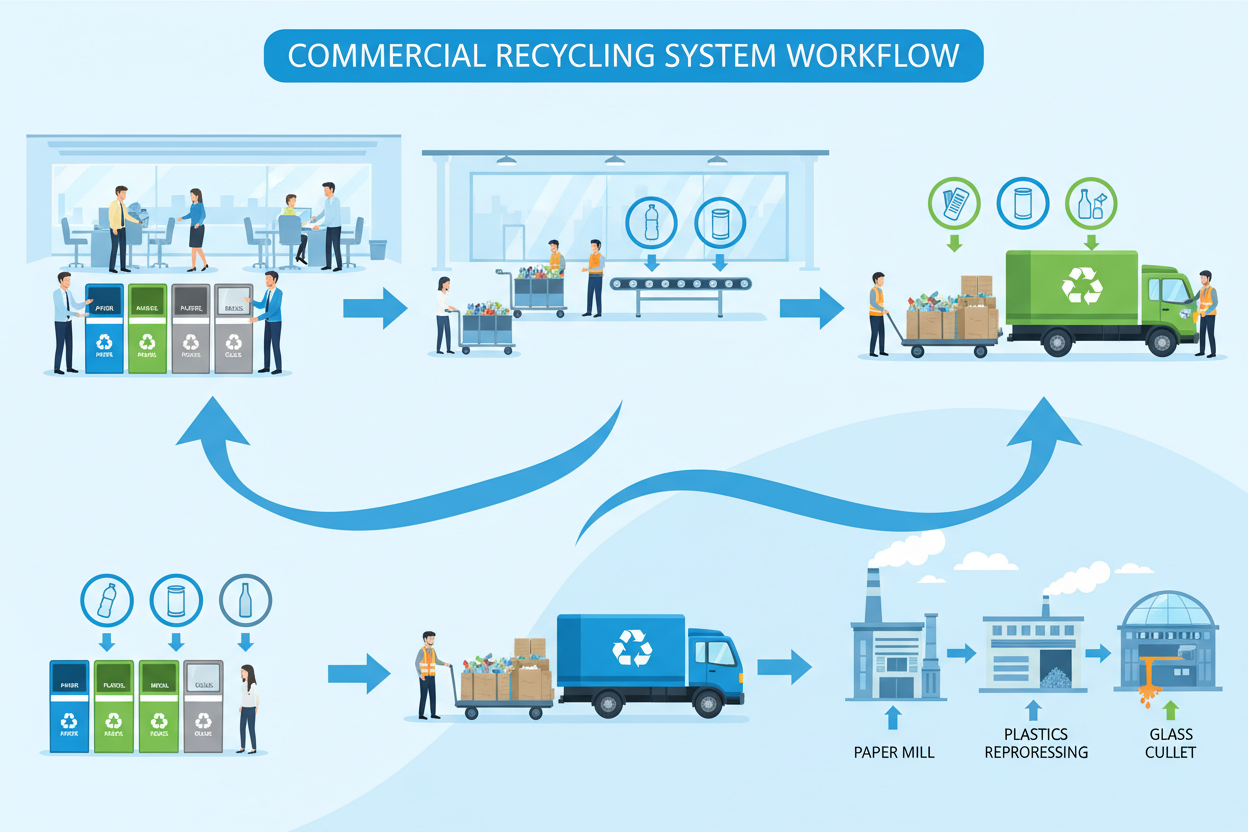

Every commercial recycling program follows three basic steps.

1. Collection and Source Separation

Your recycling journey begins at the source. Businesses use commercial recycling bins strategically placed throughout their facilities to collect different material streams. Materials are thrown away into bins, keeping the recyclable and non-recyclable materials in different containers.

Most modern programs use single-stream recycling, where all approved materials go into one container. Some businesses prefer multi-stream systems that separate paper, plastic, glass, and metal at the point of disposal. The choice depends on your local recycling facility's capabilities and your waste volume.

Here's what works best:

- Place bins next to every trash can so recycling becomes the easy choice

- Use clear signage showing exactly what goes where

- Match bin sizes to your waste generation patterns

- Schedule pickups frequently enough to prevent overflow

A general guideline is to have at least one trash can and one recycling bin for every 30 to 35 employees. High-traffic areas like break rooms, cafeterias, and loading docks need extra capacity.

2. Transportation to Processing Facilities

On the scheduled collection days, a business's waste collector will arrive to empty the bins, taking the general waste to landfill and the recyclable material to a recycling treatment facility. Collection trucks deliver loads directly to a Materials Recovery Facility (MRF), pronounced "murf."

Some areas use transfer stations as an intermediate step. These temporary holding points consolidate materials before shipping them to the actual recycling facility, which makes sense when MRFs are located far from collection routes.

3. Sorting at Materials Recovery Facilities

This is where the magic happens. MRFs use a combination of human workers and machines to sort mixed recyclables into separate, clean material streams ready for remanufacturing.

Inside a Materials Recovery Facility

Think of an MRF as a highly organized assembly line running in reverse. Instead of building products, it breaks down mixed materials into their basic components.

Receiving and Weighing

Most MRFs have a scalehouse, where giant scales weigh the truck and material together and then subtract the weight of the truck to determine how much material is coming into the facility. This data helps track volumes and calculate processing costs.

Trucks dump their loads onto a tipping floor. A mechanical loader pushes materials onto the main conveyor belt, starting their journey through the facility.

Pre-Sorting: Removing Contaminants

Workers observe the materials as they move along the conveyor belt and remove common contaminants like plastic bags, clothing, diapers, candy wrappers, expanded polystyrene, garden hoses, food scraps, holiday lights, hazardous materials like propane tanks and batteries. These items can damage equipment, cause fires, or contaminate clean recyclables.

This human element remains critical. While machines have become smarter, people still catch problems that automated systems miss.

Mechanical Sorting

After pre-sorting, materials move through several automated separation stages:

Screens and Discs: Star screens or disc screens separate materials by size. Cardboard and large paper items bounce along rotating discs while smaller items fall through gaps. A density separator removes glass from the stream by vibrating it through fine metal screens, then knocking it out with air knives or strong puffs of air.

Magnetic Separators: Strong magnets pull ferrous metals (steel and tin cans) out of the stream.

Eddy Current Separators: These create magnetic fields that repel non-ferrous metals like aluminum cans, launching them off the belt into separate collection bins.

Optical Sorters: Using infrared sensors, these machines identify different types of plastics by their resin codes (PET, HDPE, PP, etc.) and blast them with jets of air into the correct bins.

Quality Control and Baling

Each material is then compressed and packaged into bales. Paper products might be baled together. Plastics get sorted by type and color before baling. Aluminum and other metals are compacted separately.

Glass is instead crushed and put into containers which are then sold to manufacturers who remelt the glass and turn it into new glass products. The crushed glass, called cullet, can be separated by color since clear, green, and brown glass have different market values.

Quality control teams inspect bales to check contamination levels. Clean materials fetch higher prices. Contaminated bales might be rejected by buyers, sending them to landfills instead.

Setting Up Your Business Recycling Program

Understanding how the system works helps you design a better program. Here's how to start or improve your recycling efforts.

Step 1: Assess Your Waste Stream

The first step to recycling is knowing what you are throwing away. What volume and types of materials are you throwing in the trash, and what could be recycled? To answer that, you need to do a waste sort or waste assessment.

Walk through your facility and note where different materials accumulate. Offices generate mostly paper. Warehouses produce cardboard. Restaurants create glass bottles, food containers, and organic waste. Your waste profile determines which bins you need and where to place them.

Step 2: Choose the Right Commercial Recycling Bins

Container selection matters more than you might think. The wrong bins create confusion and contamination.

Consider these factors:

- Capacity: Match bin size to the volume of recyclables you generate in each area

- Opening type: Restricted openings help people put the right materials in each bin

- Durability: Indoor bins can be lighter, but outdoor bins need weather resistance

- Visibility: Bright colors and clear labeling increase participation

Nova Recycling Bins from Sunasha Distribution offer multiple sizes for different business needs, from compact 2-gallon desk bins to large 22-gallon curbside containers. Their clear labeling and durable construction make them suitable for offices, schools, warehouses, and institutional settings.

Step 3: Place Bins Strategically

Place trash cans and recycling bins in easily accessible areas. Consider the flow of foot traffic within your commercial space and identify high-traffic zones, such as entrances, break rooms, and common areas.

Follow these placement guidelines:

- Put recycling bins wherever you have trash cans

- Keep bins visible but not blocking walkways

- Create recycling stations in high-generation areas

- Match bin types to the materials generated in each location

For outdoor areas, place recycling bins on the ground at the curb, do not stack, and keep at least three feet of clear space on all sides. Don't position bins near trees, utility poles, or other obstacles that could interfere with collection.

Step 4: Train Your Team

Employee education forms the backbone of any successful workplace recycling program. Even the most well-designed system will fall short without proper employee understanding and buy-in.

Create simple, visual training materials showing what belongs in each bin. Use pictures rather than text when possible, as images cross language barriers. Address common questions about items people struggle to categorize, like plastic cups, food containers with residue, or paper with staples.

Designate recycling champions in each department to answer questions and report problems. Track your progress and share results with employees. People feel motivated when they see their efforts making a measurable difference.

Step 5: Work With the Right Hauler

Not all recycling services are equal. When selecting or reviewing your collection provider:

- Ask which materials they accept

- Confirm they use a reputable MRF

- Request bin cleaning services if needed

- Negotiate pickup frequency based on your volume

- Get competitive bids to ensure fair pricing

If your hauling contract is up for renewal, consider requesting competitive bids from other local haulers. Some businesses share haulers with nearby companies to reduce costs when individual volumes are low.

Common Materials Businesses Recycle

Commercial recycling programs typically handle these materials:

Paper and Cardboard

Office paper, cardboard boxes, and packaging materials are the highest-volume recyclables for most businesses. In 2021, the UK managed to recycle around 80 percent of paper and cardboard, showing strong infrastructure for these materials. Keep paper clean and dry. Remove packing tape from boxes when possible.

Plastics

Bottles, containers, and packaging marked with recycling symbols 1 through 7 can often be recycled. Check with your local facility since not all accept every plastic type. Rinse containers before recycling to prevent contamination.

Metals

Aluminum cans, steel food containers, and scrap metal have good recycling markets. Aluminium can recycling is a highly efficient process which saves up to 95 percent of the energy required to create new aluminium from raw bauxite ore.

Glass

Bottles and jars can be recycled endlessly without quality loss. If done correctly, 100 percent of the glass can be recycled. This means 1 glass bottle melted down equals 1 new glass bottle. Separate broken glass to protect workers.

Organic Waste

Food scraps and compostable packaging are gaining attention. Many jurisdictions now require businesses to separate organic waste for composting or anaerobic digestion rather than sending it to landfills.

Benefits of Commercial Recycling Programs

Why invest time and resources into recycling? The returns are tangible.

Cost Savings: For every ton of garbage diverted from the landfill, $34.75 in disposal costs is avoided. Collection fees still apply, but tipping fees at recycling facilities are often lower than landfilling costs or non-existent. Some clean materials like cardboard and aluminum even generate revenue.

Environmental Impact: Recycling reduces the need to extract and process raw materials, which saves energy and cuts greenhouse gas emissions. Each year the MRF prevents around 70,000 tonnes of carbon dioxide equivalents from entering the atmosphere.

Brand Reputation: Customers increasingly prefer businesses that demonstrate environmental responsibility. A visible recycling program shows your commitment to sustainability.

Employee Engagement: People want to work for companies that share their values. Offering easy recycling options helps attract and retain employees who care about environmental issues.

Regulatory Compliance: Many jurisdictions require businesses to recycle. Property owners with buildings in the seven-county metro area that contract for four cubic yards or more of trash per week must recycle at least three materials. Staying ahead of regulations protects you from fines and future requirements.

Challenges in Commercial Recycling

Understanding common obstacles helps you avoid them.

Contamination

The biggest problem facing recycling systems is contamination. When non-recyclables get mixed with clean materials, entire loads can become worthless. One greasy pizza box can contaminate a bale of otherwise recyclable cardboard. Plastic bags tangle in sorting equipment, requiring shutdowns for manual removal.

Education and clear signage help. So does making it harder to contaminate bins through restricted openings designed for specific materials.

Inconsistent Rules

Recycling guidelines vary by location. What's recyclable in one city might be trash in another. This creates confusion for multi-location businesses and employees who move between facilities.

Work with your hauler to create location-specific guidelines. Post them prominently near bins and include them in employee training.

Low Participation

If recycling requires extra effort, many people default to throwing everything in the trash. Distance matters. If someone walks 25 to 30 steps without seeing a bin, they might just toss their trash on the ground.

Make recycling the easy choice by placing bins strategically and keeping them well-maintained. Empty bins before they overflow. Replace damaged bins quickly.

Cost Concerns

Some businesses hesitate to invest in recycling infrastructure. They see upfront costs for bins and collection services without calculating long-term savings from reduced trash disposal and potential revenue from recyclables.

Calculate your true waste management costs including disposal, labor, and space. Factor in avoided tipping fees and commodity revenue. Many businesses find recycling programs pay for themselves within a year or two.

How Sunasha Distribution Supports Commercial Recycling

Sunasha Distribution, based in Ontario, Canada, specializes in wholesale recycling and waste management solutions for businesses across Canada and the USA. Their Nova Recycling Bins line offers durable, clearly labeled containers designed for commercial and institutional use.

Nova bins come in sizes ranging from compact 2-gallon kitchen bins to large 22-gallon curbside containers. They're built for daily use in offices, schools, warehouses, and public facilities. Available through wholesale accounts, these bins help businesses implement effective recycling programs without compromising on quality or visibility.

Sunasha Distribution also carries Eco-Way pest control products and Rodentex bait stations, providing comprehensive facility management solutions beyond just recycling equipment.

The Future of Commercial Recycling

Technology continues improving sorting efficiency. Artificial intelligence and robotics are making optical sorters more accurate. Some facilities now use AI to identify contamination patterns and provide feedback to collection routes that need additional education.

Chemical recycling processes are emerging that can handle plastics currently considered non-recyclable. These technologies break plastics down to their molecular components, allowing them to be rebuilt into virgin-quality materials.

Extended producer responsibility laws are shifting costs from municipalities and businesses to manufacturers. This creates incentives for companies to design products that are easier to recycle.

Single-use plastic bans and minimum recycled content requirements are becoming more common. Businesses that build strong recycling programs now will find themselves better prepared for future regulations.

Frequently Asked Questions

Q: What materials can my business recycle?

Accepted materials vary by location and hauler. Most programs take paper, cardboard, plastic bottles and containers (types 1 and 2), aluminum and steel cans, and glass bottles. Check with your local recycling facility for a complete list. Materials like plastic bags, foam, and contaminated food containers are typically not accepted in commercial programs.

Q: How do I reduce contamination in my recycling bins?

Start with clear, visual signage showing exactly what goes in each bin. Use restricted openings that make it physically harder to put wrong items in. Train employees regularly on proper sorting. Consider placing bins in areas where you can monitor them, like near break rooms rather than individual desks. Regular audits help identify problem areas.

Q: What size commercial recycling bins does my business need?

Base bin size on your waste volume. Small offices might need 11-gallon desk bins, while loading docks require large 22-gallon or even wheeled containers. Monitor how quickly bins fill up. If they overflow before the next collection, you need larger bins or more frequent pickups. If they're rarely half-full, downsize to reduce costs and space.

Q: How often should commercial recycling be collected?

Collection frequency depends on your volume. Small offices might need weekly pickup. Restaurants and retailers might require daily or multiple times per week. Match pickup frequency to bin capacity so containers don't overflow. Overflowing bins create mess and discourage participation. Your hauler can adjust schedules based on seasonal variations in your waste generation.

Q: Can commercial recycling programs actually save money?

Yes. Recycling reduces landfill tipping fees and can generate revenue from valuable materials like aluminum and clean cardboard. Many businesses find that recycling lowers their total waste management costs within 12 to 24 months. Calculate your current disposal costs per ton and compare them to recycling costs. Factor in avoided fees and potential commodity revenue. The savings often exceed the program costs.